关于TGHA9010材质—―KUMABEAR (TGHA9010)

水力发电机、汽轮发电机停机制动所使用的制动器风闸摩擦板,目前面临着如下问题:现有的电机制动闸块生产工艺中使用的原料大多是以石棉为主加上金属丝与粘合剂,这种工艺生产出来的摩擦闸块寿命低,同时刹车时粉尘大,并且因含有不规则、未经处理的金属丝,使得制动摩擦时产生火花,这种现象对工作现场有极大的危害,更甚由于石棉中含有致癌物质,不利于工作人员的健康。诸多客户提出了解决方案的诉求。

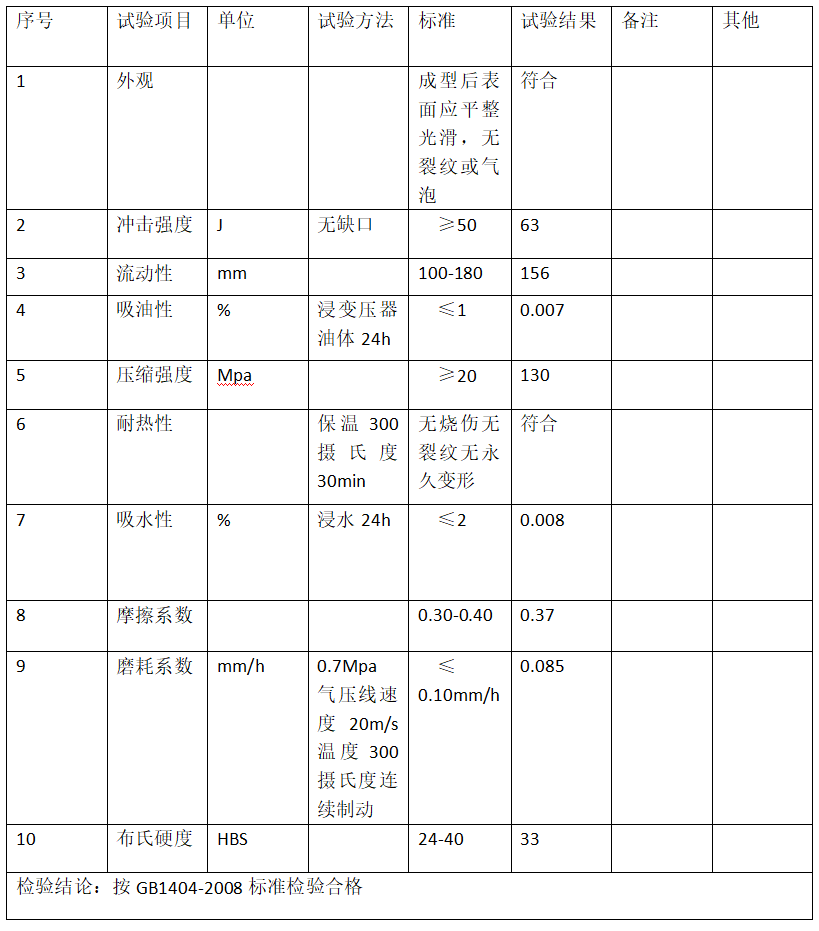

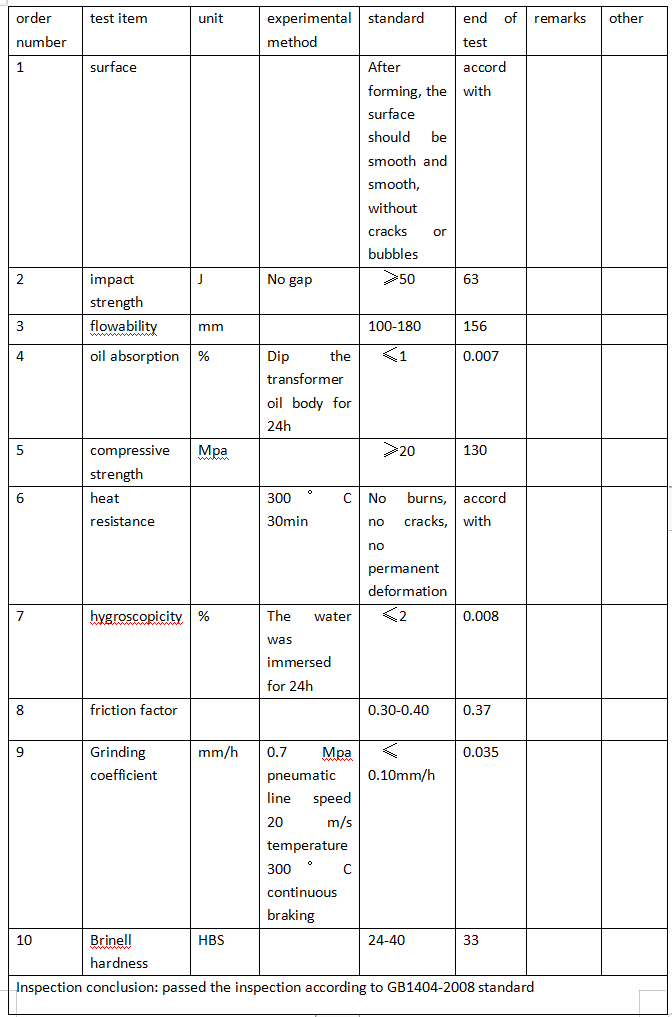

KUMABEAR针对这个现象,经过三年多的研发,目前提供了一种无石棉、增韧的制动闸块的生产工艺,由该工艺生产出的制动闸块使用寿命长、极大避免摩擦时产生的火花。VULTURE 将这种材料命名为 TGHA9010。

The brake air brake friction plate used for the shutdown braking of hydroelectric generators and steam turbinegenerators is currently facing the following problems:

Most of the raw materials used in the current production process of motor brake pads are asbestos, along with metal wires and adhesives. The friction brake pads produced by this process have a low lifespan and generate large amounts of dust during braking. Additionally, due to the presence of irregular and untreated metal wires, sparks are generated during braking friction, which poses a great threat to the workplace.Moreover, asbestos contains carcinogenic substances, which are not conducive to the health of workers. Many customers have raised demands for solutions. VULTURE has developed a production process for asbestos freeand toughened brake pads after more than three years of research and development to address this phenomenon The brake pad has a long service life and greatly avoids sparks generated during friction. VULTURE named this material TGHA9010.

TGHA9010牌号材质所制造的水轮机、汽轮机制动器风闸摩擦板具有耐磨、抗压、降低火花的特点。

The friction plate ofthe air brake ofthe water turbineand

steam turbine brake made of TGHA9010 material has the

characteristics of wear resistance, pressure resistance

and spark reduction.

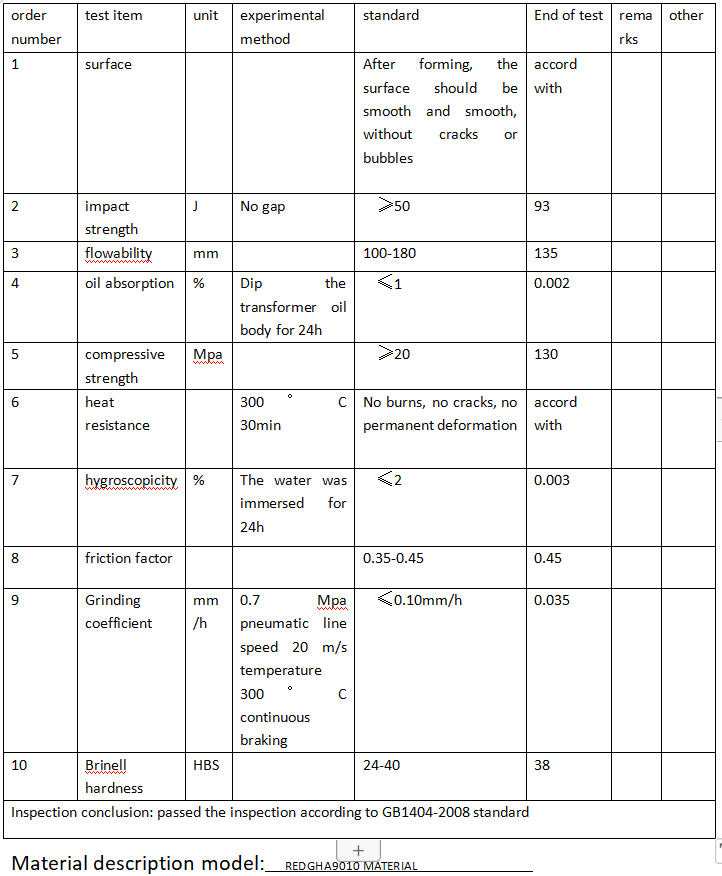

REDGHA9010材质是 KUMABEAR针对环境更为恶劣的水电站所提出的更为高耐磨的风闸摩擦板材料, REDGHA9010的具指名称为特陶双改性合金烧结材质,这种材质摒弃了传统的复合材料模式,采用多改性的方式,使基础材料体现出优势特性、降低或屏蔽劣势特性,REDGHA9010 中含有了金属元素,但是在实际挂机实验过程中,火花现象出现的概率、频率更为低下。

REDGHA9010 material is a higher wear-resistant friction plate material for wind gates proposed by KUMABEAR for hydropower stations with more harsh environments. REDGHA9010 is specifically named TeTao Double Modified Alloy Sintered Material, which abandons the traditional composite material mode and adopts a multi modification method to make the basic material reflect advantageous characteristics and reduce or shield disadvantageous characteristics. Even though REDGHA9010 contains metal elements,the probability and frequency ofspark phenomenon are lower in actual hanging experiments.

REDGHA9010 摩擦材料风闸板具有更高的耐磨度,极大的降低了磨损率,它的使用寿命为 TGHA9010 材质的约 10-20倍左右,为市面普通摩擦材料的30倍左右。同时保持着较高且稳定的摩擦系数。

REDGHA9010 friction material air brake plate has higher wear resistance, greatly reducing wear rate. Its service life is about 10-20 times that of TGHA9010 material and about 30 times that of ordinary friction materials on the market. Simultaneously maintaining a high and stable coefficient of friction.

虽然REDGHA9010材质摩擦板,生产过程繁琐、材料成本高昂、售价较为昂贵,但是,REDGHA9010 可以缩减水电站风闸磨擦板的更换频率,

降低人员工作强度,延长机械机组工作效能。

REDGHA9010 material friction plates have a complicated production process, high material costs, and relatively expensive prices,REDGHA9010 can reduce the frequency of replacing friction plates for wind gates in hydropower stations, lower personnel workload, and extend the efficiency of mechanical units.

TGHA9010 还是 REDGHA9010 牌号材质,由他们所制造的摩擦板已经经过实践与时间的检验,并得到了良好的反馈。

TGHA9010 is still made of REDGHA9010 grade material, and the friction plates manufactured by them have been tested through practice and time, and have received good feedback.