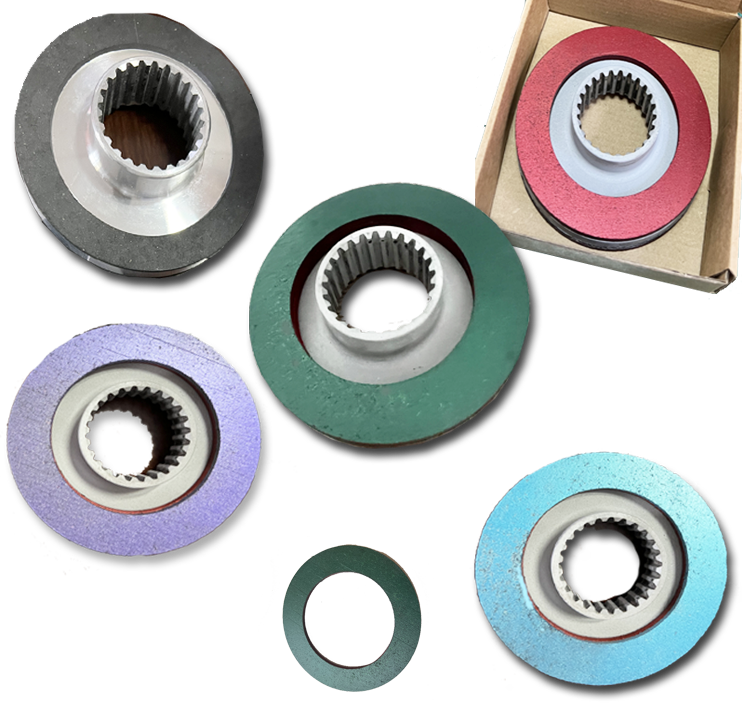

电磁抱闸摩擦材料

KUMABEAR 致力于降低 抱闸摩擦片的运行噪音

KUMABEAR is committed to reducing the operating noise of brake friction plates

偏航工作噪音的现象会严重影响生态环境,同时也会造成制动衬垫伤盘。针对如何降低制动时的噪音问题,KUMABEAR从衬垫(降噪材料)角度来提出解决方案。KUMABEAR 通过研发自产的温敏感改性树脂及规律油膜层破坏的硬质材方式,提出了KUMABEAR-F6降噪型偏航摩擦片材料

The phenomenon of yawing work noise can seriously affect the ecological environment and also cause damage to the brake pads. KUMABEAR proposes a solution from the perspective of pads (noise reducing materials) to reduce the noise during braking. KUMABEAR has proposed the KUMABEAR-F6 noise reducing yaw friction plate material through the development of self-produced temperature sensitive modified resins and hard materials with regular oil film layer damage.

KUMABEAR 致力于提高 电机、电磁制动器抱闸摩擦片 高耐温、高耐磨、降尘 属性

KUMABEAR is committed to improving the high temperature resistance, wear resistance, and dust reduction properties of electric motors, electromagnetic brakes, and brake pads

在电机电磁制动器适用的各种境况中,尤其是风电、起重机、电梯、水力发电、传输机等领域,抱闸摩擦片的“不耐磨”现象尤为严重,这严重影响了整体机械设备寿命,也不利于安全事故防范

In various situations where motor electromagnetic brakes are applicable, especially in wind power, cranes, elevators, hydropower, transmission machines and other fields, the “non wear resistance” phenomenon of brake friction plates is particularly serious, which seriously affects the overall service life of mechanical equipment and is not conducive to safety accident prevention

KUMABEAR 针对不同领域客户反映的问题,设计了多种牌号,不同抱闸摩擦片专长属性的解决方案

KUMABEAR has designed multiple grades and solutions with different expertise attributes for brake friction plates to address issues raised by customers in different fields